Description

A manufacturing robot works by following a set of instructions programmed into its controller. The controller sends signals to the robot’s actuators, which move the robot’s joints in a specific sequence. The robot’s sensors provide feedback to the controller about its position and orientation, so that the controller can make adjustments as needed.

Here is a more detailed explanation of the steps involved:

- The human operator programs the robot to perform a specific task. This is typically done using a computer interface.

- The robot controller receives the program and stores it in memory.

- The controller begins executing the program, sending signals to the robot’s actuators.

- The actuators move the robot’s joints in the sequence specified by the program.

- The robot’s sensors monitor the robot’s position and orientation and provide feedback to the controller.

- The controller uses the feedback to make adjustments to the robot’s movements as needed.

- The robot repeats this process until the task is complete.

Manufacturing robots can perform a wide variety of tasks, such as welding, painting, assembly, and material handling. They are typically used in repetitive and dangerous tasks that are difficult or impossible for humans to perform.

Here are some examples of how manufacturing robots are used in different industries:

- Automotive industry: Robots are used to weld car bodies, paint cars, and assemble cars.

- Electronics industry: Robots are used to place components on circuit boards, solder components, and inspect circuit boards.

- Aerospace industry: Robots are used to drill holes in aircraft parts, rivet aircraft parts together, and inspect aircraft parts.

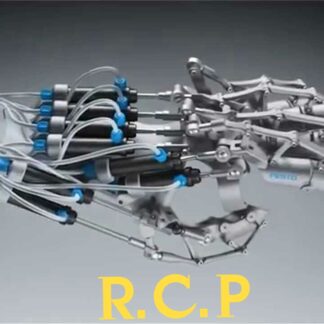

The main components:

- Controller: The controller is the brain of the robot, responsible for communicating with the other components and directing the robot’s movements. It typically consists of a computer and specialized software.

- Sensors: Sensors provide feedback to the controller about the robot’s environment and its own movements. This feedback is used to ensure that the robot is operating safely and accurately.

- Robot arm: The robot arm is the physical structure of the robot. It consists of a series of joints that allow the robot to move its end effector in different ways.

- End effector: The end effector is the tool attached to the end of the robot arm. It is used to perform the robot’s task, such as welding, painting, or assembling parts.

- Drive: The drive system provides the power to move the robot’s joints. It can be powered by electricity, pneumatics, or hydraulics.

How a manufacturing robot works:

- The controller receives a program from the human operator. This program specifies the sequence of movements that the robot must perform to complete the task.

- The controller sends signals to the drives, which power the robot’s joints.

- The sensors monitor the robot’s movements and provide feedback to the controller.

- The controller uses the feedback to adjust the robot’s movements as needed.

- The robot repeats this process until the task is complete.

Manufacturing robots are used in a wide variety of industries, including automotive, electronics, and aerospace. They can be used to perform a wide range of tasks, such as welding, painting, assembly, and material handling. Robots can help to improve productivity, quality, and safety in manufacturing operations.

Here are some examples of how manufacturing robots are used in different industries:

Reviews

There are no reviews yet.