Description

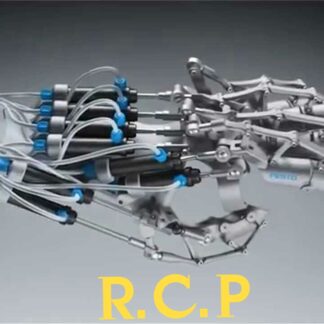

An industrial robotic arm is a type of robot commonly used in manufacturing and other industries to perform tasks that are dangerous, repetitive, or difficult for humans to do.

They are typically six-jointed, although some may have more or fewer. Each joint has a motor that allows it to rotate in a certain range of motion. The end of the arm, called the end effector, can be equipped with a variety of tools, such as grippers, welders, or paint sprayers.

Industrial robotic arms are programmed to follow a specific set of instructions, which they can repeat precisely and tirelessly. This makes them ideal for tasks such as:

-

- Assembly: Putting together parts to create a finished product

-

- Welding: Joining pieces of metal together

-

- Painting: Applying paint to a surface

-

- Packaging: Putting products into boxes or other containers

-

- Machine tending: Loading and unloading materials into machines

Benefits of using industrial robotic arms:

-

- Increased productivity: Industrial robots can work 24/7 without fatigue, which can significantly increase production output.

-

- Improved quality: Robots can perform tasks with a high degree of precision, which can lead to fewer defects in products.

-

- Reduced costs: Automating tasks with robots can free up human workers for other tasks and can also reduce the need for safety measures and equipment.

-

- Improved safety: Robots can be used to perform tasks in hazardous environments, which can help to protect workers from injuries.

Challenges of using industrial robotic arms:

-

- High initial cost: Industrial robots can be expensive to purchase and install.

-

- Programming complexity: Programming robots can be complex and require specialized skills.

-

- Job displacement: The use of robots in some industries has led to job losses for human workers.

Overall, industrial robotic arms are a powerful tool that can help businesses improve productivity, quality, and safety. However, it is important to carefully consider the costs and challenges of using robots before making a decision to implement them.

Reviews

There are no reviews yet.